|

|

|

|

| Home | Light Duty Machines | Heavy Duty Machines | Special Machines | Table-Up Machines |

| Tooling & Broaches | Broaching Examples | Used Machines | Production Broaching | Contact |

What is Broaching?Broaching is a machining process that pushes or pulls

a cutting tool (called a broach) over or through the surface being

machined. Broaches are referred to as multiple-point linear-travel

cutting tools and are used to produce flat, circular, and even extremely

intricate profiles, as seen from a section perpendicular to the tool

travel. A broach is a series of single-point tools arranged

successively in the axial direction along a tool body or holder. Each

sequential tooth varies in size and shape in a manner that allows each

tooth to cut a chip of the proper thickness. |

|

|

The concept of broaching as a legitimate machining process can be traced back to the early 1850s. Early broaching applications were cutting keyways in pulleys and gears. After World War 1, broaching contributed to the rifling of gun barrels. Advances in broaching machines and form grinding during the 1920s and 30s enabled tolerances to be tightened and broaching costs to become competitive with other machining processes. Today, almost every conceivable type of form and material can be broached. |

|

|

|

|

|||

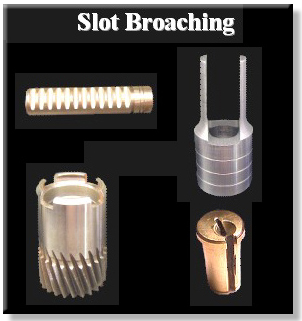

| Straddle Broaching | Slot Broaching | Internal Broaching | |||

| These are a few examples of typical straddle broach operations. These cuts are achieved by using opposing straddle broaches and simple hydraulic clamping. Most straddle squares and hexes can be completed in a single broach pass with the use of an automatic indexer, collet and anvil part support. | Some examples of typical single and multiple pass slot broaching, and Lock Cylinder Broaching achieved by using standard / interchangeable tooling. To accommodate various part sizes and shapes, the fixtures can be used with an almost unlimited range of work holding jaws, adaptors, and locator nests, either made in your own tool room, or furnished by Ty Miles. | Here are some examples of parts that were internally broached to produce internal involutes, irregular shapes, spline broaching, keyway broaching, or most any hole configuration you can imagine. This can be done on a multi station machine, completing up to 3 or 4 parts per machine cycle. | |||

Automotive Broaching Machines for the Automotive Industry

|

||

|

|

Miles Broaching has supplied the automotive industry and automotive suppliers worldwide, with thousands of broaching machines and automated manufacturing systems. Typical automotive applications would be broaching transmission shafts, steering wheel hubs, steering yokes, broaching gears of all types, both Internal and External broaching, fuel intake components, and many different automotive parts. Broaching works extremely well for the automotive industry due to the high volume, tight tolerance applications that are needed to provide uninterrupted production of precision automotive parts. Ty Miles offers many types and styles of broaching machines to the Automotive Industry, from stand alone models to broaching machines integrated into an automotive manufacturing cell. |

|

| Some of our Customers Include: | Industries that utilize broaching | ||

| Daniel Defense Beretta USA Corp. Harley-Davidson The Torrington Company General Motors Corp. Ford Motor Company Daimler Chrysler G.E. Aircraft Engines Whirlpool Corporation Schlage Locks |

Sturm, Ruger Black and Decker Caterpillar TRW Eaton Corp. Ingersoll Rand Kohler Co. Briggs and Stratton Delphi Automotive Systems Baxter Healthcare |

* Aerospace * Automotive * Appliance * Firearms * Locks * Defense * Mining Equipment * Energy Production * Medical |

|

| Customers from many diverse industries decidedly choose the broaching advantage for the superior quality that broaching can achieve, while saving time and money. See our sample of industries that have benefited from Miles Broaching technology. | |||

|

©

2018 Ty Miles, Inc. No duplication or reproduction without

author's consent. All Rights Reserved. 9855 Derby Lane, Westchester IL 60154 USA / 708-344-5480 stevem@tymiles.com |